Boxall Service & Repair Ltd

Boxall Service & Repair Ltd provide specialist servicing, repairs and sales of electrical and mechanical equipment, including motors, fans, pumps, booster sets, gearboxes and control gear.

Our Atex Hazardous Areas team are in high demand and are one of a limited number of trained and accredited Atex specialists in the country with the capacity to design, install, inspect and maintain electrical equipment & installations within environments that include explosive gasses, vapours, fuel filling stations and other intrinsically safe systems.

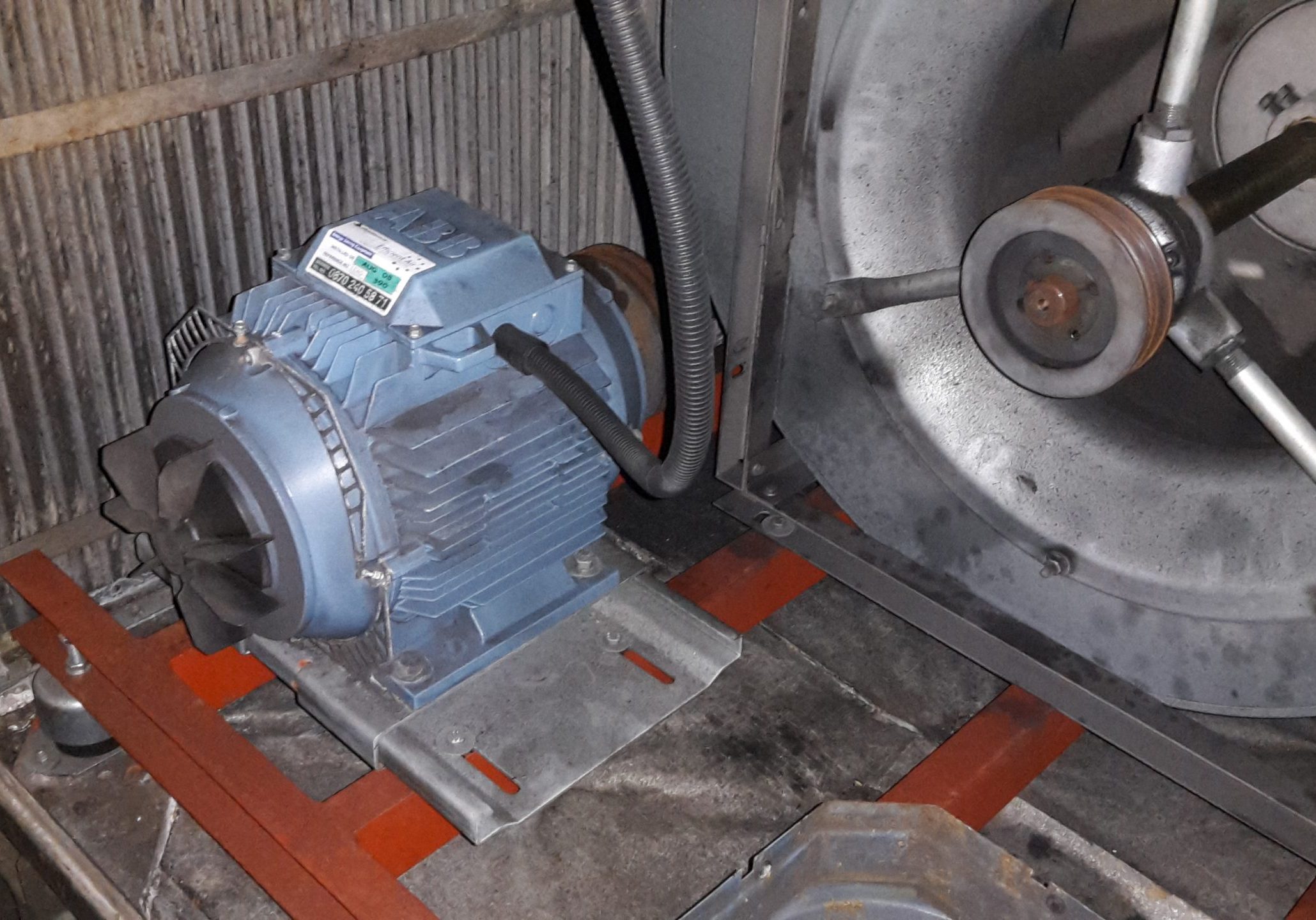

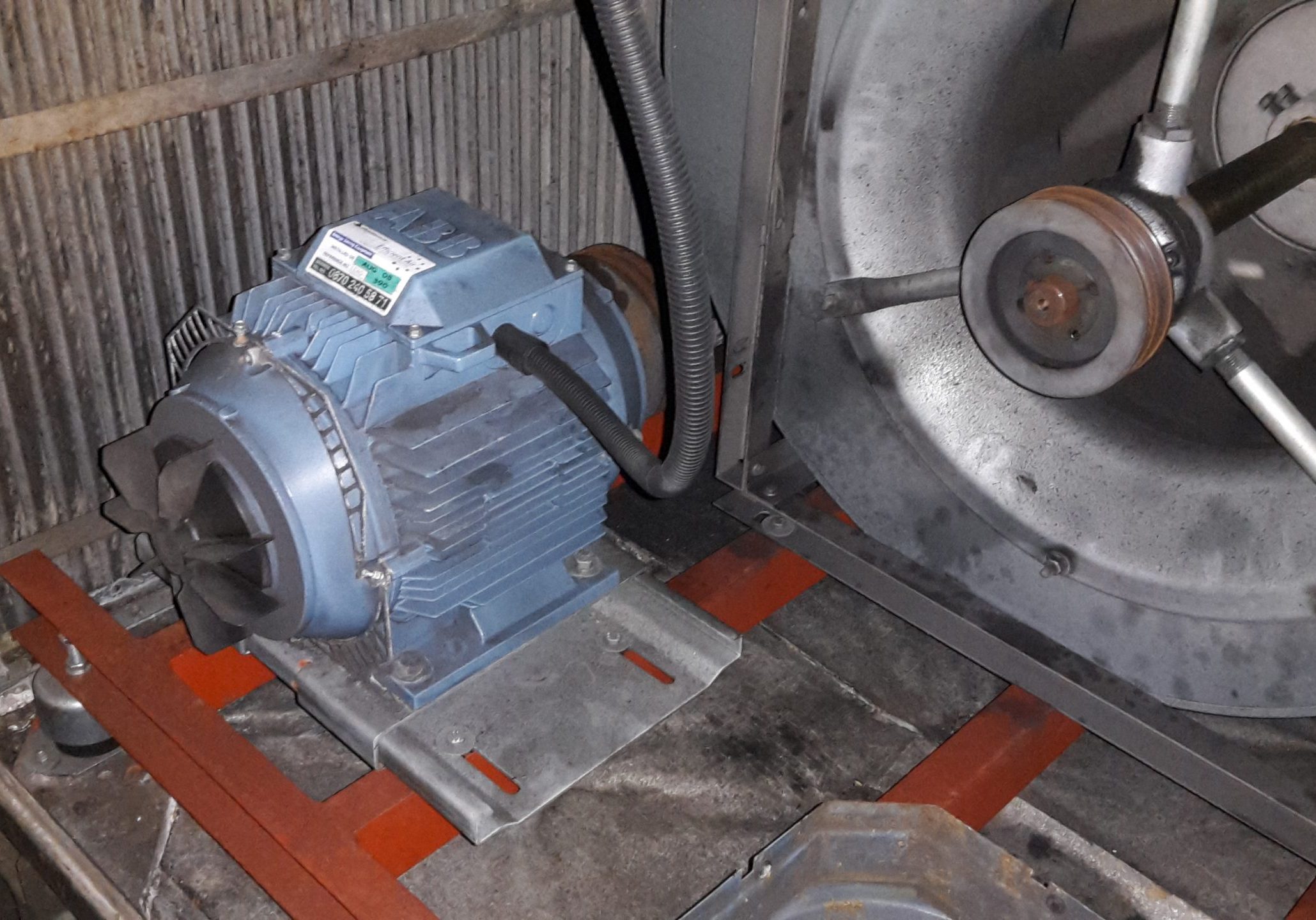

The motor rewind team work to save on the expense of purchasing a replacement motor. Their expertise is especially sought after for motors which are no longer in production when the modern equivalent has a completely different footprint. They love to repair rather than scrap!

With a fully equipped workshop, incorporating lathes, mills, presses, balancing, test bay, paint and DC undercutting equipment we aim to get our clients equipment back on-site as quickly as possible to minimise client downtime.

Motor Rewinds

Armature & Slip Ring Refurbishment

Bearings

Stockists for Brook Crompton & TEC

Locked Rotor

DC to AC Conversions

ATEX Hazardous Area

Dynamic Fan Balancing

Inverter Drive Repairs

Our inverter drives repair team use the same techniques and procedures undertaken during the original manufacturing process and are an authorised Parker SSD drive repair centre. All drives undergo electrical safety analysis (HI-POT) to ensure pre-power testing compliance prior to dispatch. We also offer full load testing, using dynamic chokes and full dynamic motor testing if required.

We supply a wide range of AC/DC drives, including single, three phase and line to line.

Supply

Install

Commission

Dynamic Choke/Motor Test

AC10, AC30, 590, 690, 890, 890

Hi-Pot Test

Parvex and Servo Motors

Installation / Commissioning

With over 85 years of experience providing FM, M&E services, our highly skilled teams understand the challenging environments our clients operate in. We help address compliance concerns and work to agreed industry standards, including SFG 20 where appropriate.

Covering a diverse range of industries; including airports, healthcare, sawmills, brickworks, leisure centres, breweries and pharmaceuticals, we know how to minimise downtime and help keep your business operating.

In-House

Our well-equipped workshops routinely handle motors up to 5 tonnes/180Kw. Plant includes lathes, mills, presses, balancing, test bay, paint room and DC undercutting. Supporting our FM & M&E divisions our workshop handles direct enquires from SME’s and larger corporate clients looking to harness our unique expertise and skill set.

On-Site

For clients requiring immediate assistance, we are happy to visit and provide an initial diagnostic report. We can often provide an immediate fix, but should the issue be more significant, our report includes recommendations and timescales to help get your business operational again as quickly as possible.