Page 50 - Westbury Filtermation Catalogue

P. 50

Product Data Sheet

2

PUSH 150 Glove Box Push Through HEPA Filter

APPLICATIONS

Designed to ensure the safe

operation of chemical,

pharmaceutical, nuclear & • H14 to EN1822

2

biological isolators, Push

Cylindrical glove box filter has • No metal parts

been designed using the very

• Fits all standard 150mm (6”) bore canisters

latest materials to provide lower

resistance, longer life and • Modern ergonomic design

stability even at isolator breach

pressures. • Low resistance

• Individually tested & certified

CONSTRUCTION

2

The Push 150 contains no metal • Full traceability

parts and is therefore totally

3

incinerable for ease of disposal. • May be used at up to 100m /hr

This feature, combined with the

continuous safety edges of the

moulding also means the product

TECHNICAL INFORMATION

is safe and simple to use.

Dimensions: 148mm (5.8”) Diameter x 172mm (6.8”) Long

The modern ergonomic design

makes handling simple, even Efficiency: H14 to EN1822 - Individually tested.

when being manipulated with the 3 3

Rated Capacity: ≤100m /hr Initial Pressure loss at 40m /hr: 110Pa (0.44”WG)

thickest isolator gloves.

3

Westbury’s integrated moulded Integrity retained at: 120m /hr (70.6 CFM) Burst Pressure exceeds: 1000Pa

continuous gasket ensures a

perfect air seal every time.

COMPONENTS OF CONSTRUCTION

The product’s increased media

Filter Media: Glass Fibre Paper H14 Filter Media Separators: Synthetic Polymer Hot Melt

surface area ensures the lowest

possible pressure whilst Pleat Pack Joint Adhesive: PVA Adhesive Plastic Mesh: Extruded Polypropylene

operating at full capacity. This in

Frame & Endcap: ABS Plastic Seal: TPE Plastic

turn results in lower energy

demand in operation. Potting Adhesives: Polyol/Polyisocyanate mixture Label: Polyester

The standard operational flow

3

rate of 40m /hr (23.5 CFM) runs

2

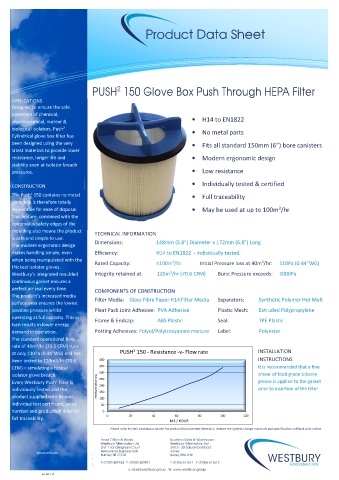

at only 110Pa (0.44”WG) and has PUSH 150 - Resistance -v- Flow rate INSTALLATION

been tested to 120m3/hr (70.6 400 INSTRUCTIONS

CFM) – simulating a typical 350 It is recommended that a fine

300

isolator glove breach. 250 smear of food grade silicone

2

Every Westbury Push filter is 200 grease is applied to the gasket

individually tested and the PRESSURE DROP (Pa) 150 prior to insertion of the filter

product supplied with its own 100

individual test certificate, serial 50

number and production date for 0

0 20 40 60 80 100 120

full traceability.

M3 / HOUR

Please note: In their continuous search for product improvement Westbury reserve the right to change materials and specifications without prior notice.

Doc

WDATA-P150-005

Ref: DST-T-V1