Page 49 - Westbury Filtermation Catalogue

P. 49

APPLICATIONS

Suitable for numerous

applications including:

• Smoke removal • Ultra High Velocity HEPA

• Asbestos removal • Available in H13 &H14

• Cleanrooms • Low Resistance

• Clean booths

• Decontamination • Long Life

• Individually Tested & Certified

• Safe-change applications

• Suits numerous applications

CONSTRUCTION • Timber Case for easy incineration

The filter media packs for the • Robust construction

UHV-W High Velocity Hepa

Filter are manufactured from

a continuous length of

superior quality micro-glass

paper media. The media is

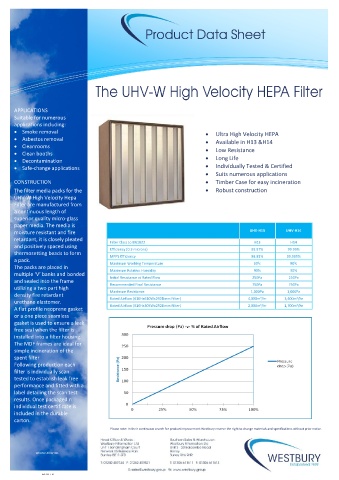

moisture resistant and fire UHV-H13 UHV-H14

retardant, it is closely pleated

Filter Class to EN1822 H13 H14

and positively spaced using

Efficiency (0.3 microns) 99.97% 99.99%

thermosetting beads to form

MPPS Efficiency 99.95% 99.995%

a pack.

Maximum Working Temperature 90 c 90 c

0

0

The packs are placed in

Maximum Relative Humidity 90% 90%

multiple ‘V’ banks and bonded

Initial Resistance at Rated Flow 250Pa 250Pa

and sealed into the frame

Recommended Final Resistance 750Pa 750Pa

utilizing a two part high

Maximum Resistance 1,000Pa 1,000Pa

density fire retardant

3

3

Rated Airflow (610Hx610Wx292Dmm Filter) 4,000m /hr 3,400m /hr

urethane elastomer.

Rated Airflow (610Hx305Wx292Dmm Filter) 2,000m /hr 1,700m /hr

3

3

A flat profile neoprene gasket

or a one piece seamless

gasket is used to ensure a leak

free seal when the filter is

installed into a filter housing.

The MDF frames are ideal for

simple incineration of the

spent filter

Following production each

filter is individually scan

tested to establish leak free

performance and fitted with a

label detailing the scan test

results. Once packaged n

individual test certificate is

included in the durable

carton.

Please note: In their continuous search for product improvement Westbury reserve the right to change materials and specifications without prior notice.

Doc

WDATA-UHVW-001

Ref: DST-T-V1